Subli-light InkJet Transfer Paper

Product Detail

Direct InkJet Sublimation transfer paper HT-150R for 100% cotton fabric

Direct Subli Inkjet Transfer Paper (HT-150R)can be printed by all inkjet printers with sublimation ink, or water based dye ink, pigment ink, and then transferred onto dark or light colored 100% cotton fabric, cotton/polyester blend, 100%polyester, cotton/spandex blend, cotton/nylon etc. by a regular household iron or heat press machine. Decorate fabric with photos in minutes. after transferring, get great durability with image retaining color, wash-after-wash.

Advantages

■ High printing resolution up to 1440dpi, with bright colors and good color saturation!

■ It can print and transferred a variety of fabrics, such as 100% cotton, polyester-cotton blends, etc.

■ Transferred by heat press machine, Mini heat press, or home iron.

■ The back paper can be peel off with hot easily in 5 seconds after transferring.

Direct InkJet Sublimation transfer paper HT-150R for 100% cotton fabric

More Application

Product Uasge

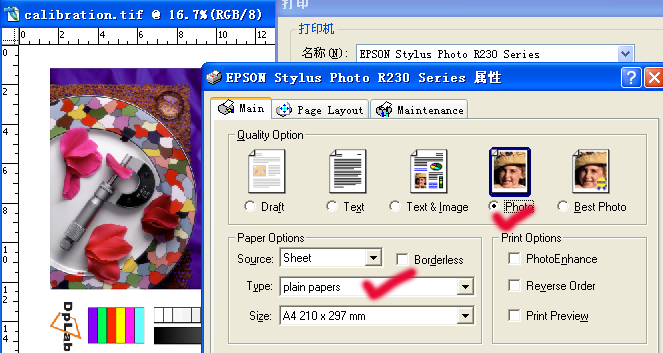

4.Printer Recommendations

It can be printed by all kinds of inkjet printers such as :Epson Stylus Photo 1390, R270, R230, PRO 4400, Canon PIXMA ip4300, 5300, 4200, i9950, ix5000, Pro9500, HP Deskjet 1280, HP Photosmart D7168, HP Officejet Pro K550 etc.

and some of laser printers ( Please testing before use) such as: Epson AcuLaser CX11N, C7000, C8600, Fuji Xerox DocuPrint C525 A, C3210DX, Canon laser shot LBP5600, LBP5900, LBP5500, LBP5800, CanonCLC1100, CLC1130, CLC1160, CLC5000, CanoniRC2620, 3100, 3200 etc.

5.Printing setting

Quality Option: photo(P), Paper Options: Plain papers

6.Iron-On transferring

■ Prepare a stable, heat-resistant surface suitable for ironing on.

■ Preheat the iron to the cotton setting, recommended ironing temperature 200°C.

■ Briefly iron the fabric to ensure that it is completely smooth, then place the transfer paper onto it with the printed image facing downwards.

a. Do not use the steam function.

b. Make sure that the heat is evenly transferred over the entire area.

c. Iron the transfer paper, applying as much pressure as possible.

d. When moving the iron, less pressure should be given.

e. Don’t forget the corners and edges.

■ Continue ironing until you have completely traced the sides of the image. This entire process should take about 60-70 seconds for an 8”x 10” image surface. Follow-up by ironing the whole image quickly, heating all of the transfer paper again for approximately 10-13 seconds.

■ Peel the back paper starting at the corner in 5 seconds after the ironing process.

7.Heat press transferring

■ Setting heat press machine 185°C for 15~25 seconds using moderate or high pressure. the press should snap closed firmly.

■ Briefly press the fabric 185°C for 5 seconds to ensure that it is completely smooth.

■ Place the transfer paper onto it with the printed image facing downwards.

■ Press machine 185°C for 15~25 seconds.

■ Peel the back paper starting at the corner in 5 seconds after transferring

8.Washing Instructions:

Wash inside out in COLD WATER. DO NOT USE BLEACH. Place into the dryer or do hang to dry immediately. Please do not stretch the image transferred or the T-shirt as this may cause cracking to occur, If cracking or wrinkling does occur, please place a sheet of greasy proof paper over the transfer and heat press or iron for a few seconds making sure to press firmly over the entire transfer again. Please remember to not iron directly on the image surface.

9. Finishing Recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.

Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.