ODM Supplier China Luminous Heat Transfer Vinyl Blue/Green for Garment/Clothing

Product Detail

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for ODM Supplier China Luminous Heat Transfer Vinyl Blue/Green for Garment/Clothing, If you pursuit the Hi-quality, Hi-stable, Competitive price parts, company name is your best choice!

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for China Metallic Heat Transfer Vinyl, Heat Transfer Glitter Vinyl, We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don’t hesitate to contact us. We will try our best to meet your needs.

1.General Description

Dark(opaque) inkjet transfer paper can be printed by all inkjet printers with water based dye ink, pigment ink, and then transferred onto dark or light colored 100% cotton fabric, cotton/polyester blend, 100%polyester, cotton/spandex blend, cotton/nylon etc. by a regular household iron or heat press machine. Decorate fabric with photos in minutes, get great durability with image retaining color, wash-after-wash.

2.Application

Dark(opaque) inkjet transfer paper is ideal for customizing dark, or light colored T-shirts, aprons, gift bags, mouse pads, photographs on quilts and more. The outstanding feature of this product is excellent washable after transferring, and fine cuttable by cutting plotter, so It is idea for printing by inkjet printers, then cut by desk cutting plotter such as Silhouette CAMEO, GCC i-Craft, Circut etc. to make a design.

3.Advantage

■ Customize fabric with favorite photos and color graphics.

■ Designed for vivid results on dark, white or light-colored cotton or cotton/polyester blend fabrics

■ Ideal for personalizing T-shirts, canvas bags, aprons, gift bags, mouse pads, photographs on quilts etc.

■ Iron on with a regular household iron & heat press machines.

■ Good washable and keep coloration

■ More flexible and more elastic

Our company since its inception, usually regards product high-quality as company life, constantly boost manufacturing technology, boost product excellent and continuously strengthen company total excellent administration, in strict accordance using the national standard ISO 9001:2000 for ODM Supplier China Luminous Heat Transfer Vinyl Blue/Green for Garment/Clothing, If you pursuit the Hi-quality, Hi-stable, Competitive price parts, company name is your best choice!

ODM Supplier China Metallic Heat Transfer Vinyl, Heat Transfer Glitter Vinyl, We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don’t hesitate to contact us. We will try our best to meet your needs.

Product Uasge

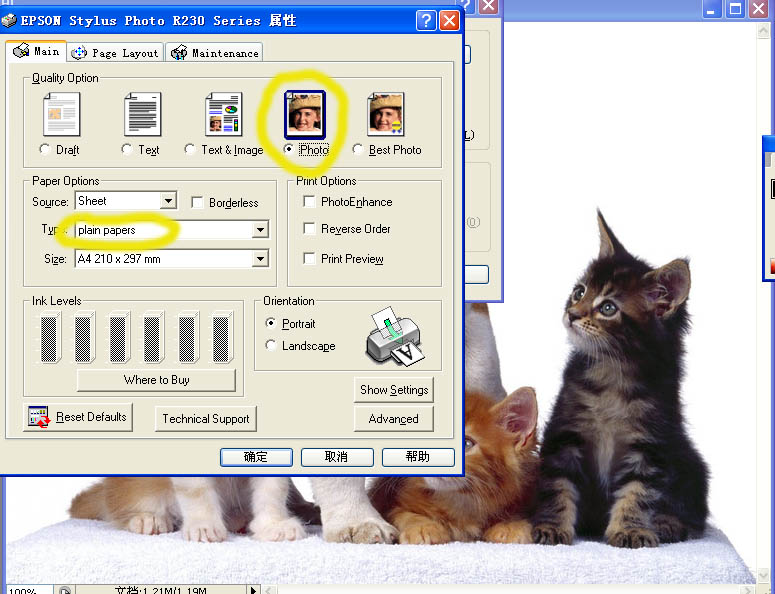

4.Printer Recommendations

It can be printed by all kinds of inkjet printers such as : Epson Stylus Photo 1390, R270, R230, PRO 4400,Canon PIXMA ip4300, 5300, 4200, i9950, ix5000, Pro9500,HP Deskjet 1280, HP Photosmart D7168 , HP Officejet Pro K550 etc. and some of laser printers or color lasers Machines such as: Epson AcuLaser CX11N, C7000, C8600, Fuji Xerox DocuPrint C525 A, C3210DX, Canon CLC1100, CLC113, Konica Minolta bizhub C series.

5.Printing setting

Quality Option: photo(P), Paper Options: Plain papers. and the printing inks is ordinary water-based dye, pigment ink or sublimation ink.

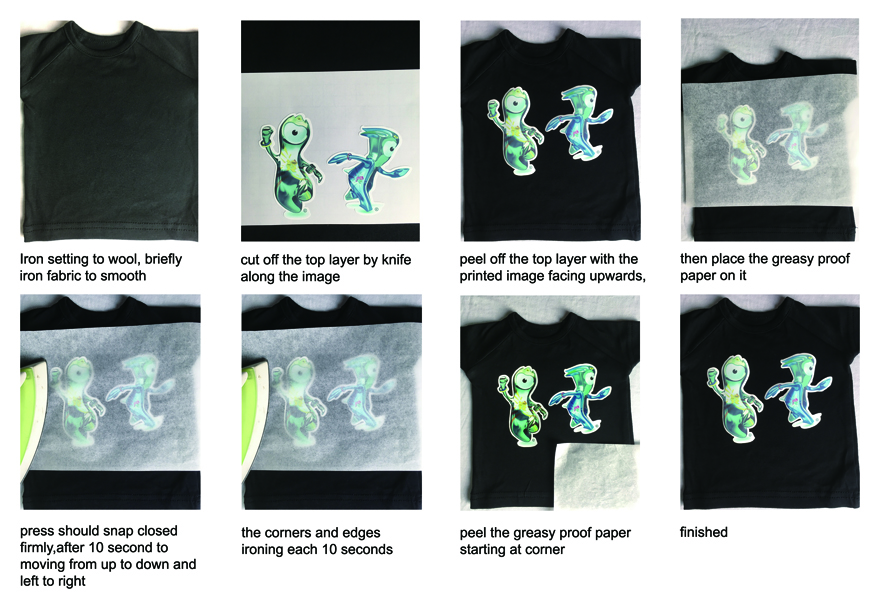

6.Iron-On transferring

a. Prepare a stable, heat-resistant surface suitable for ironing on.

b. Preheat the iron to the wool setting. Do not use the steam function

c. Briefly iron the fabric to ensure that it is completely smooth

d. Put transfer paper into inkjet printer for printing with coated side up, After drying for several minutes.

e. The printed image will be cut off with a cutting tool, and the white side of the image will be kept at about 0.5cm to prevent the ink from seeping and staining the clothes.

f. Peel the image line off from the backing paper gently by hand, place the image line face upwards on the target fabric, then cover a greaseproof paper on the surface of the image, finally, cover a layer of cotton fabric onto the greaseproof paper. Now, you can iron the cotton fabric thoroughly from left to right and up to down.

g. When moving the iron, less pressure should be given. Don’t forget the corners and edges

h. Continue ironing until you have completely traced the sides of the image. This entire process should take about 60-70 seconds for an 8”x 10” image surface

i. After ironing, move away cotton fabric, then cooling for about several minutes, Peel the grease proof paper starting at the corner

j. It is possible to use the same the grease proof paper five times or more, if there are no residual inks, Please keep the grease proof paper, Maybe, You will use it next time.

7.Heat press transferring

1). Setting a heat press at 165~175°C for 25~35 seconds using moderate pressure.

2). Briefly heat the fabric for 5 second to ensure that it is completely smooth.

3). Leave the printed image to dry for approx.5 minutes, cut out the image around the edges by cutting plotter.

4). Place the adhesive ployester film on it, then peel the image line off from the backing paper gently by hand.

5). Place the image line facing upwards onto the target fabric

6). Place the cotton fabric onto it.

7). After transferring for 25seconds , move away cotton fabric, then cooling for about several minutes,

Peel the adhesive ployester film starting at the corner.

8.Washing Instructions:

Wash inside out in COLD WATER. DO NOT USE BLEACH. Place into the dryer or do hang to dry immediately. Please do not stretch the image transferred or the T-shirt as this may cause cracking to occur, If cracking or wrinkling does occur, please place a sheet of greasy proof paper over the transfer and heat press or iron for a few seconds making sure to press firmly over the entire transfer again.Please remember to not iron directly on the image surface.

9.Finishing Recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.