Pretty Film

Product Detail

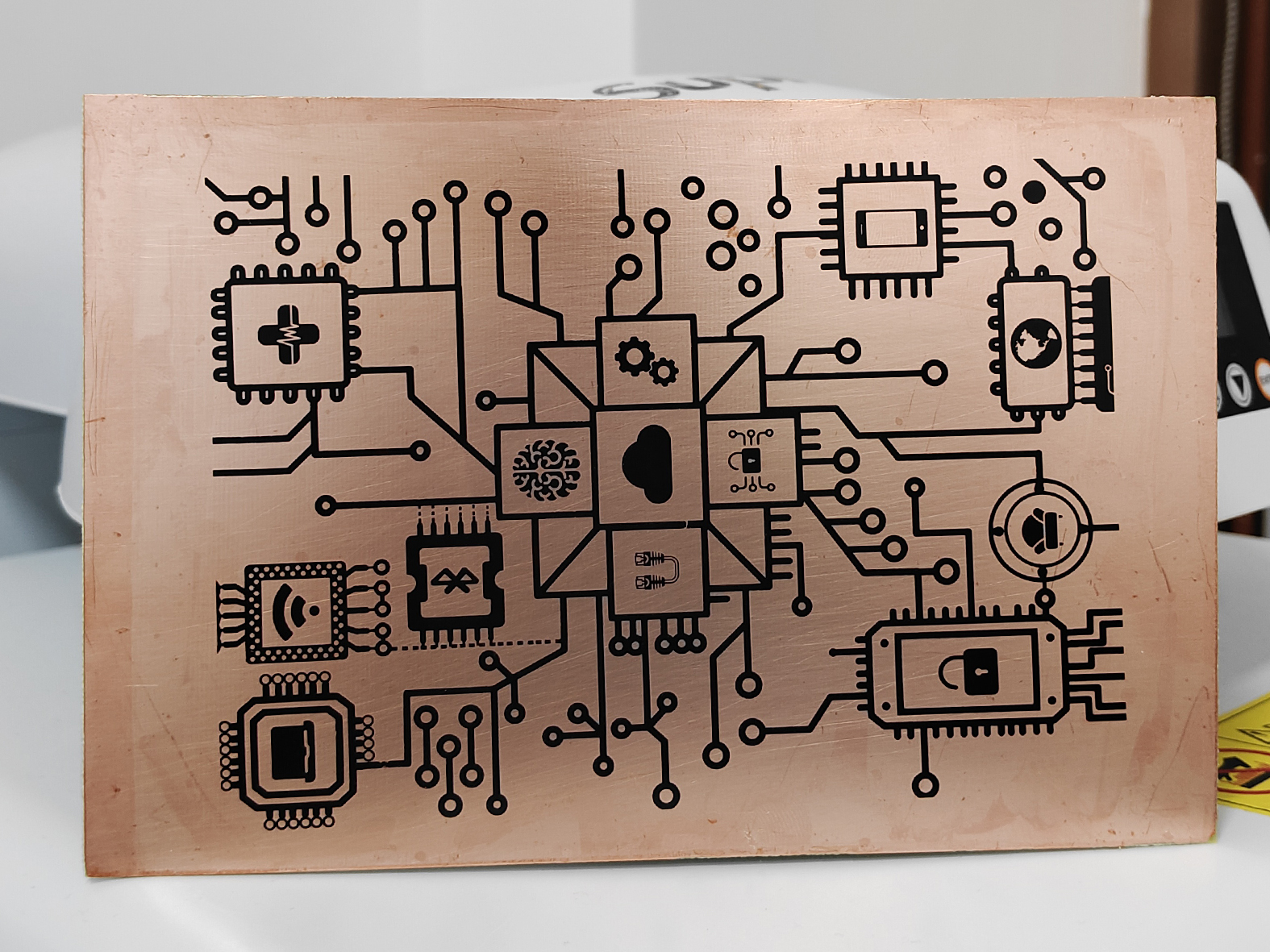

Pretty-Film (PF-150)

Un-Coated Substrate, No-Cut

Pretty-Film (PF-150) that can be used by color laser printers, or color laser copy printers with flat feed and flat output, such as OKI Data C941dn, ES9542, Konica Minolta AccurioLabel 230, for all your craft projects. Personalize and customize your project by printing unique designs on our Pretty-Film. Transfer decals onto un-coated ceramics, glass, jade, metal, plastic materials and other hard surface. After baking in an electric oven at 110°C~190°C for about 5~10 minutes, After cooling to room temperature, tear off the surface film to get the finished product. The outstanding features of the Pretty-Film are that it does not require coating, and No-Cut. It is also heat-resistant, weather-resistant and washable.

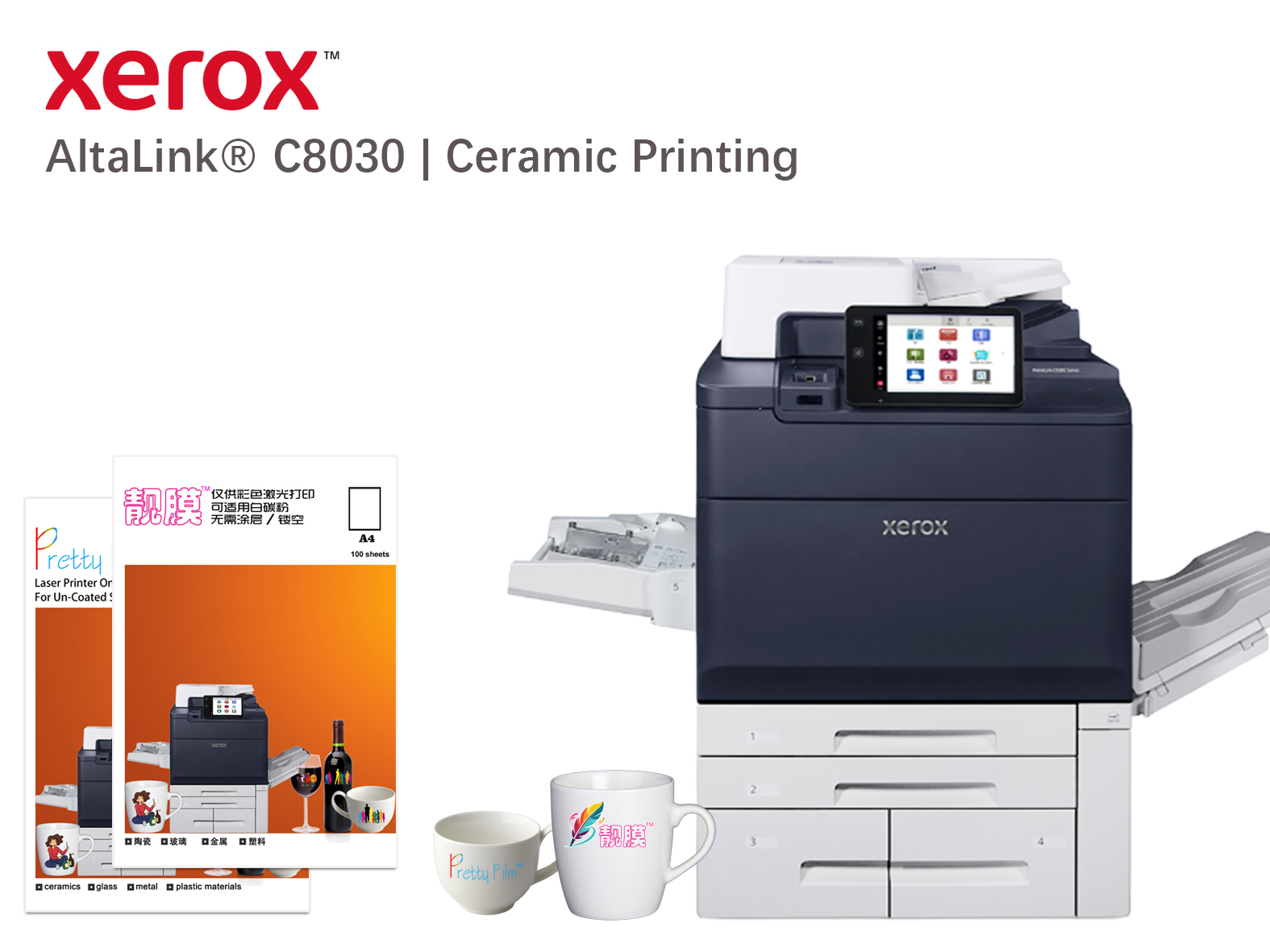

Laser Printers: laser printers with flat feed and flat output, such as OKI, Xerox, Konica Minolta etc.

Main Features: No pre-coating required, No-Cut. Heat-resistant, Weather-resistant and Washable.

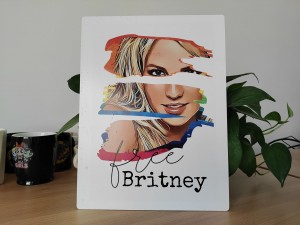

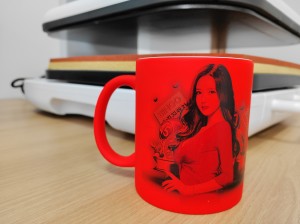

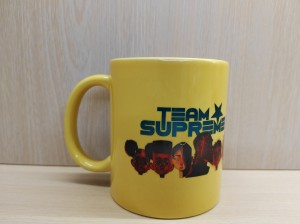

Main Markets: Make your Exclusive photos and logos of porcelain cup, ceramic mug, Glass wine, stainless steel cup, Safety Helmets etc.

Code: PF-150

Product: Pretty-Film

Size: A4 - 100sheets/package, A3 - 100sheets/package, 33cm X 300 meter/ roll

Ratio: A4 - 100sheets + Pre-Coat FJ5 50ml ( free)

Application Scenario

Advantages

■ Compatible with Universal color laser printer, color laser printer-copier, or laser label printer, such as OKI Data C941dn, ES9542, Konica Minolta AccurioLabel 230

■ No need for pre-coating, and No-Cut, heat-resistant, weather-resistant and washable.

■ Transfer decals onto un-coated ceramics, glass, jade, metal, plastic materials and other hard surface

■ Continuous paper feeding printing, no paper jam, high production efficiency

Step-by-Step Tutorial: Make Your Exclusive Photos and Images With PF-150 Pretty-Film For Un-Coated Ceramic Cup

What you can do for your craft projects with Pretty-Film (PF-150) ?

Ceramic Products :

Metal Products :

Painted surface and plastic products: :

Product Uasge

What are you going to prepare?

|

|

|

|

Color Laser Printers |

|

|

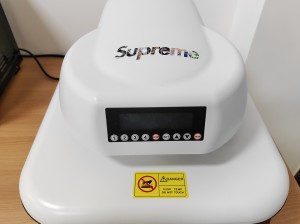

Electric oven |

|

|

Craft projects |

|

We sell consumables Pretty-Film (PF-150) only

|

Pretty-Film(PF-150) |

|

size: |

|

Pre-treatment liquid ( Pre-coat F) |

|

Matching products, no money required |

Recommended laser printers:

Color laser printers with flat paper feed and flat paper output, color laser printer-copiers or laser label printers are preferred, such as: Xerox AltaLink C8100、PrimeLink C9065,OKI C941dn,konica Minolta C221、AccurioPress C4070/C4080,Fuji Revoria Press PC1120、C5005D,Ricoh Pro C7500,Canon imagePRESS V700 etc. Since the working principle of each laser printer manufacturer and model is slightly different, please test in advance which laser printer will be suitable.

Laser Printing Settings:

Paper source (S): Multipurpose tray, Thickness (T): Thick,

Best print mode, please test in advance

Step by step from water slide to heat transfer by Pretty-Film:

step 1. Laser printing:

step 2. Pre-coating:

Soak a sanitary napkin in the Pre-Coat FJ5 pretreatment liquid and gently wipe the laser-printed coating surface. Let it dry naturally for about 5 minutes.

Note: There should be no water droplets. If there are any, wipe them dry with a dry cotton ball.

step 3. Water slide:

Soak in warm water (water temperature is about 30~60 °C) for about 30~60 seconds, until the Pretty-Film (PF-150) can be easily separated from the based paper.

step 4. Remove bubbles

With the printed surface facing down, press the backing paper to separate it from the film, leaving the film on the craft product. Press the film and gently slide it to a suitable position. Use a rubber melon or a wet towel to gently scrape the water droplets and bubbles between the film and the craft product.

step 5. baking:

Set the electric baking temperature to 150°C~190°C and the time to 5~10 minutes. The optimal temperature and time can only be determined after multiple tests.

Glass products need to be heated up slowly to the required temperature to avoid sudden temperature changes and spontaneous explosion of the glass.

Put the ceramic cup in the electric oven, close the door, and adjust the time knob to 5~10 minutes. When the baking time is reached, open the oven door, put on high-temperature resistant gloves, take out the ceramic cup, and place the cup on a heat-resistant table.

step 6. Film tearing:

Let it cool naturally for about 30~60 minutes and start to tear off the film from the corners.

Please do not try to scrape, rub or pick at the finished product, as it needs to be left for at least 24 hours to achieve the best fastness.

Finishing Recommendations

Material Handling & Storage: conditions of 35-65% Relative Humidity and at a temperature of 10-30°C.

Storage of open packages: When an open packages of media is not being used remove the roll or sheets from the printer cover the roll or sheets with a plastic bag to protect it from contaminants, if you are storing it on end, use an end plug and tape down the edge to prevent damage to the edge of the roll do not lay sharp or heavy objects on unprotected rolls and do not stack them.

3-300x225.jpg)

.jpg)